Hugh Howard ~ maintenance controller

Hugh Howard loves a challenge.

When the maintenance controller isn’t working across our nine southern wastewater treatment plants, he’s working on ways to expand his own and others’ horizons.

Two years ago, he created a community project where he engaged a team of more than 18 people from Watercare, our contractors and his social network to speak to young people about their potential career paths.

“I created a game called Discover Your Unknown World. We went to Sir Edmund Hillary Collegiate in Otara where I spoke to 60 students about igniting their curiosity and wonder about their futures and creating a bridge career pathway to those dreams using the team.

“We had civil teams, engineers, environmental scientists, female tradespeople and people from the Lord of the Rings production team and Rocket Lab. It was about showing the students that there are other jobs outside of their houses.”

He did the project as part of personal development courses he does in his spare time.

“I learned how to get outside of myself and make the uncomfortable, comfortable. It was really successful.”

Former chief operating officer Shane Morgan supported him by giving him time during the work week to pull it together.

“It’s about getting outside your comfort zone and requesting things from people. I really grew from that and it helped me with my leadership and work, being able to lead teams and create teamwork with teams.”

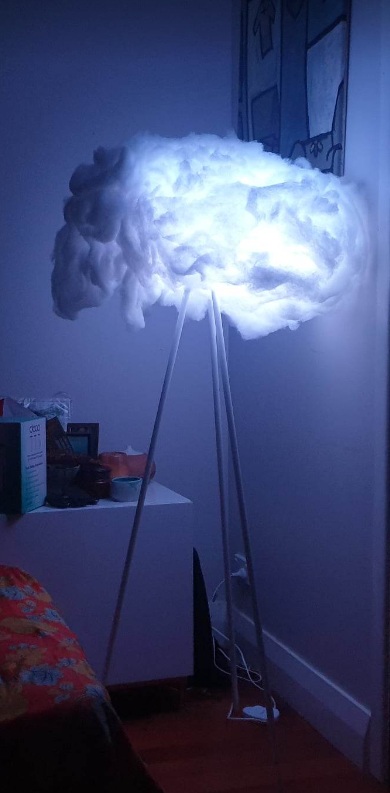

More recently, he created an art project called Glow Cloud, which involved building a physical cloud structure that glows with the next day’s weather forecast.

“I had a small team working on it. It’s a combination of art and technology, bringing them together to create something beautiful and useful.”

Hugh's art project, the Glow Cloud.

He’s hoping to have it displayed at the Maritime Museum.

“The idea is to build an art piece in a public space. It will be touring schools for students to look at.”

His interests in art, 3D printing and electronic music might not seem like they relate to a maintenance controller role, but it was his interest in technology and machinery that lead him to Watercare almost five years ago.

He originally trained as an electronic technician and worked in a wide range of industries, including asphalt manufacturing, electron microscopes, petrochemicals and electronic security and access control.

“They seem quite diverse, but they were all quite transferable. My skills were in electronic testing and measurement and instrumentation.

“I developed an interest in industrial manufacturing. My role before this was as a sales engineer, I sold to power utilities and specialised in power analysis. Before that I was installing and commissioning control systems in asphalt plants across Australia. I went from building electronic products to commissioning plants.

“Heavy machinery tickled my fancy and when I came across the Watercare role, I applied for it.”

He joined as a maintenance planner, which involved creating preventative maintenance plans for assets – in his case, wastewater treatment plants.

“Creating plans involves coordinating different tradespeople, such as electricians, mechanical fitters, instrumentation technicians and civil trades, and our external contractors to decide what needs maintaining, who is responsible for it and when it needs to be done.”

Hugh moved into a maintenance controller role, where he is accountable for the maintenance budgets of nine wastewater treatment plants.

He is based at Māngere but also looks after the Pukekohe, Beachlands, Waiuku, Kawakawa Bay, Kingseat, Waiheke, Clarks Beach and Bombay plants, and Puketutu Island.

“My job is to coordinate and manage maintenance activity to ensure that treatment assets are maintained and to manage efficiencies in time and costs compared to previous years, whilst managing risks to process, plant and people. We are accountable for the maintenance budgets for preventative maintenance, planned and unplanned maintenance and major maintenance, and capitalisation projects.”

A recent capitalisation job he ran was repairing a reactor/clarifier and it involved him leading a team of more than 20 people, including maintenance delivery, a structural engineer, health and safety, a plant manager and a contractor team doing scaffolding.

“I led that whole team from initiation to completion. It was one of the biggest jobs I’ve done and it scared the shit out of me because it was a high-risk project. The reactor/clarifier is a really important part of the wastewater treatment process and we needed to get it going again, but we needed to do it safely. There was a high risk of injury.”

One of Hugh’s skills is activating people to get on board with a project and he made sure that the team communicated to the point where “no rock was left unturned and every part of the job was known to everyone”.

“I learned that you don’t have to do things on your own. The more I developed it with others and communicated, the lower the risk became and we successfully pulled it off.

“I did the planning process and once it was planned, I brought in a good execution team and made sure that team had one leader. All decisions went through that leader. I oversaw the project but handed it to the team to manage.”

The maintenance controller role provides Hugh with a variety of challenges, which he enjoys.

“It’s probably a cliché, but no two days are the same and the scale of work can be from small to very big. I like being challenged and taking on things that will stretch me. I love going to the different sites. I go from one of the biggest wastewater treatment plants in the southern hemisphere at Māngere to the smaller ones and everything in between.

“I love the technology at the plants. I can work with big machines and small intricate ones that are just as important.”

He enjoys playing a part in making sure we provide positive outcomes for the communities we serve and the environment.

“My teammates have a wealth of knowledge and I can ask them for help or mentoring if I need it. I love seeing the different skill sets that are around. There are people here with skills I’ve never seen before. We have a good culture. I don’t want to let my teammates down and they don’t want to let me down either. Our strength is that we are here for each other and have a lot of integrity.”